COPPER ALLOY

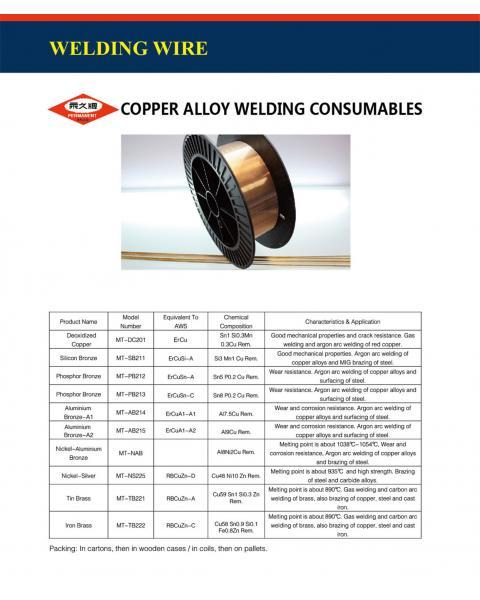

COPPER ALLOY WELDING CONSUMABLES

Product Name | Model Number | Equivalent To AWS | Chemical Composition | Characteristics & Application |

Deoxidized Copper | MT-DC201 | ErCu | Sn1 Si0.3Mn 0.3Cu Rem. | Good mechanical properties and crack resistance. Gas welding and argon arc welding of red copper. |

Silicon Bronze | MT-SB211 | ErCuSi-A | Si3 Mn1 Cu Rem. | Good mechanical properties. Argon arc welding of copper alloys and MIG brazing of steel. |

Phosphor Bronze | MT-PB212 | ErCuSn-A | Sn5 P0.2 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. |

Phosphor Bronze | MT-PB213 | ErCuSn-C | Sn8 P0.2 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. |

Aluminum Bronze-A1 | MT-AB214 | ErCuA1-A1 | A17.5Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. |

Aluminum Bronze-A2 | MT-AB215 | ErCuA1-A2 | A19Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. |

Nickel-Aluminum Bronze | MT-NAB | A18Ni2Cu Rem. | Melting point is about 1038℃-1054℃, Wear and corrosion resistance, Argon arc welding of copper alloys and brazing of steel. | |

Nickel-Silver | MT-NS225 | RBCuZn-D | Cu48 Ni10 Zn Rem. | Melting point is about 935℃ and high strength. Brazing of steel and carbide alloys. |

Tin Brass | MT-TB221 | Cu59 Sn1 Si0.3 Zn Rem. | Melting point is about 890℃. Gas welding and carbon arc welding of brass, also brazing of copper, steel and cast iron. | |

Iron Brass | MT-TB222 | RBCuZn-C | Cu58 Sn0.9 Si0.1 Fe0.8Zn Rem. | Melting point is about 890℃. Gas welding and carbon arc welding of brass, also brazing of copper, steel and cast iron. |

Packing: In cartons, then in wooden cases / in coils, then on pallets.

BRAZING AND SOLDERING CONSUMABLES

Type | Model Number | Equivalent To AWS | Specification | Melting Point | Chemical Composition | Application |

Copper Phosphorus | MT-L201 | BCuP-2 | Wire & rod, Power | 710-793 | P 7-7.5 Cu Rem | Brazing of copper and cooper alloys. |

MT-L205 | BCuP-3 | Wire & rod | 643-813 | P5.8-6.2 Ag4.8-5.2 Cu Rem. | ||

MT-L209 | BCuP-6 | Wire & rod | 643-788 | P6.8-7.2 Ag1.8-2.2 Cu Rem. | ||

Silver base | MT-L303 | BAg-5 | Wire & rod | 663-743 | Ag44-46 Cu29-31 Zn 23-27 | Brazing of copper, cooper alloys, steel and stainless steel etc. |

Packing: Wire and rod can be packed in boxes of 1kgs, then in wooden cases of 20kgs.

Packing: Powder can be packed in plastic bottles of 1kgs, then in cartons of 20kgs.